① Core Pain Points in Golf Cart Battery Market and Lithium Solution

-

Rapid range degradation: Lead-acid batteries typically have <300 cycles, with range dropping over 30% in high-temperature environments, forcing frequent daily battery changes;

-

Excessive weight load: A 48V lead-acid battery pack weighs 330 lbs (150 kg), accounting for 30% of the cart’s total weight—severely impacting maneuverability and energy consumption;

-

High maintenance costs: Requiring regular water refills and balanced charging, annual maintenance for a single course costs $800, while discarded batteries pose heavy metal pollution risks.

② Technical Advantages and Scenario-specific Applications

1. Range & Efficiency Upgrade: 18-Hole All-Day Solution

-

High energy density: 280Wh/kg density enables a 48V/105Ah lithium battery pack to achieve 50 miles (80 km) range—50% longer than lead-acid—supporting full-day 18-hole operations;

-

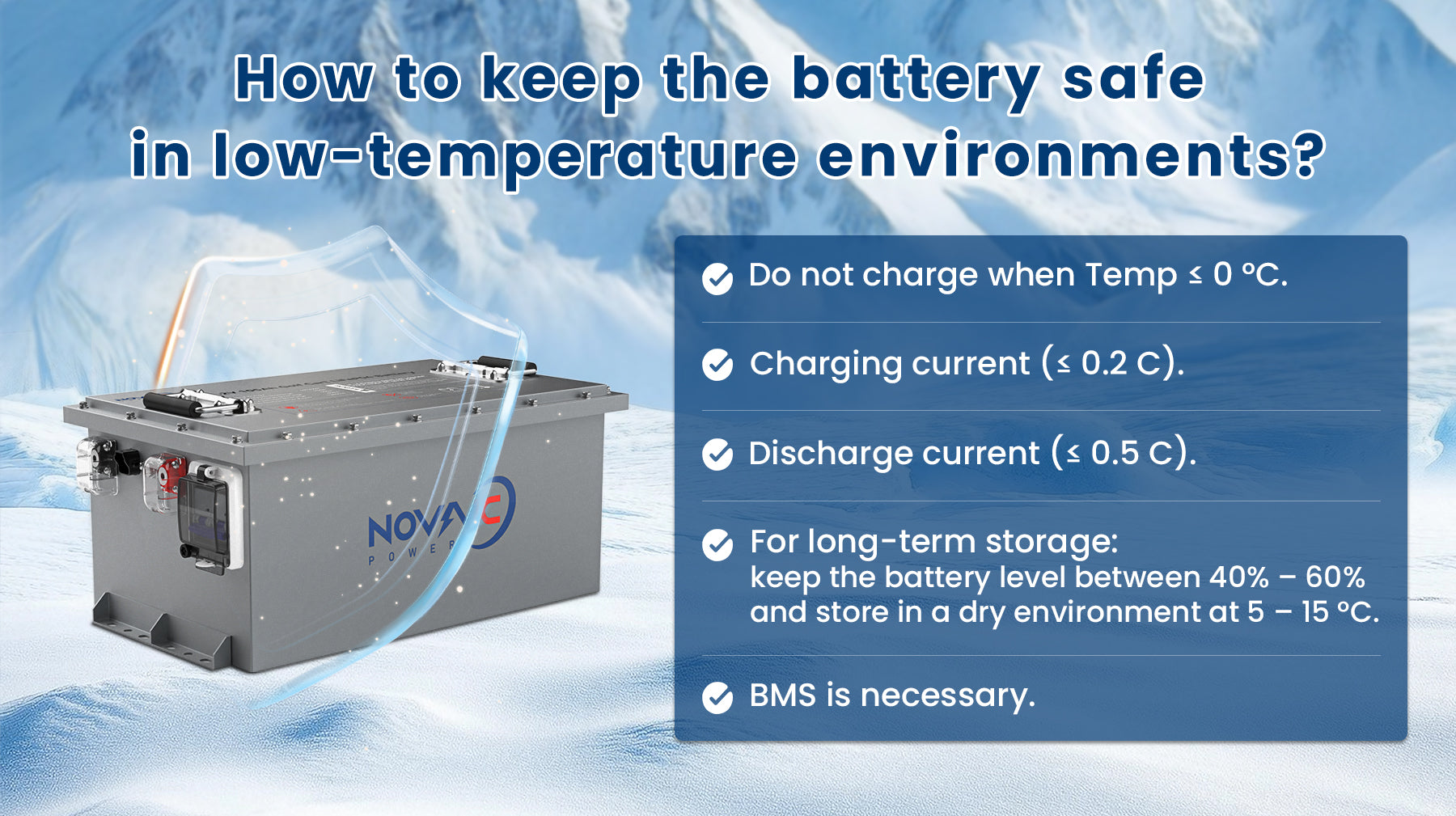

Intelligent thermal management: 8-channel temperature sensors maintain 95%+ discharge efficiency in -20°F~+140°F (-20°C~+60°C), eliminating winter preheating needs for northern courses;

-

20A fast charging: Fully charges in 2 hours. Paired with course chargers, it replenishes 80% energy during lunch breaks, solving the "overnight charging" constraint of lead-acid batteries.

2. Lightweight & Safety Design: Tournament-Grade Standards

-

Weight optimization: 132 lbs (60 kg) lithium pack lowers cart CG by 7.87 inches (20 cm), improving cornering stability by 30% for hilly terrains;

-

Military-grade protection: IP65 waterproof/dustproof design allows direct cart washing without water ingress;

-

BMS battery management: Real-time monitoring of voltage, current, and temperature with <10ms fault response for overcharge/short-circuit protection, compliant with UL 2580 safety standards.

3. Full Lifecycle Cost Optimization: From "Consumable" to "Asset"

|

Metric

|

Traditional Lead-Acid

|

Novaicpower Lithium

|

5-Year Total Cost Comparison

|

|

Acquisition Cost

|

$300~$600

|

$1,300~$2,000

|

Lithium costs 217% more initially

|

|

Cycle Life

|

300 cycles@80%DOD

|

4,000 cycles@100%DOD

|

Replacement frequency down 92.5%

|

|

Maintenance

|

$800/year

|

$100/year (annual inspection)

|

5-year savings: $3,500

|

|

Residual Value

|

None

|

30% cost recovery

|

$390-$600 post-retirement

|

③ Golf Cart Lithium Battery Selection Guide & Industry Trends

1. Key Parameters to Prioritize

-

Cell type: Avoid low-cost ternary lithium; prefer LiFePO4 with thermal runaway temp >500°C;

-

BMS features: Ensure balanced charging (cell voltage difference <5mV) and cloud monitoring;

2. Policy & Technology Trends

-

Regulatory drive: The EPA’s proposed 2027 eco-tax on lead-acid batteries is making lithium the compliance choice;

-

Smart upgrades: Next-gen lithium batteries will integrate UWB positioning for real-time course tracking, slated for 2025 mass production.

Conclusion: From "Power Supply" to "Smart Operations"

-

72-hour pre-fault alerts to prevent downtime;

-

Hole-by-hole energy consumption visualization for charging optimization;

-

Accurate carbon footprint tracking to meet ESG requirements.

Share:

Why Cell Balancing is Crucial for Battery Performance and Longevity

Commonalities and Comparison Between Energy Storage Batteries and Power Batteries