When discussing the differences between BMS systems (Battery Management Systems) and PCB BMS (Protection Circuit Boards), we need to clarify their functions, application scenarios, and design complexities.

Definition and Functions of BMS Systems ①

BMS (Battery Management System) is an abbreviation for Battery Management System, primarily used to monitor and manage the status of battery packs. Its core functions include:

-

State Monitoring: Real-time monitoring of parameters such as voltage, temperature, and current of individual battery cells to ensure they operate within safe limits.

-

Protection Functions: Preventing overcharging, over-discharging, short circuits, and overcurrent situations to extend battery lifespan.

-

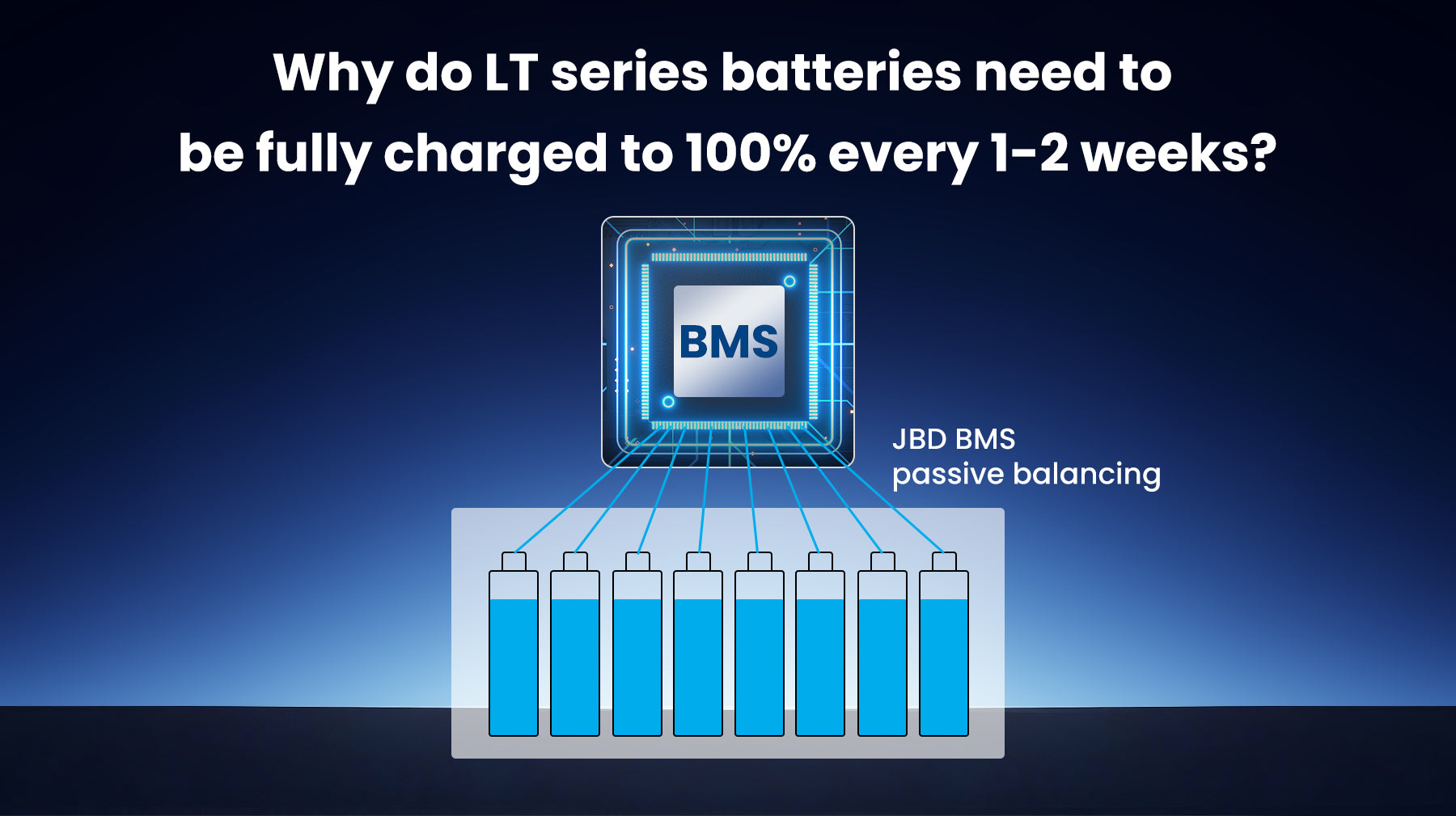

Balancing Management: Ensuring that the charge levels of individual cells within a battery pack are balanced, avoiding performance degradation caused by imbalances.

-

Data Communication: Interfacing with other devices (like power control systems, energy management systems, etc.) for information exchange, achieving coordinated control of the system

[3].

BMS systems are typically used in large battery packs, such as those in electric vehicles and energy storage systems, capable of handling complex battery management tasks.

Definition and Functions of PCB BMS ②

PCB (Printed Circuit Board) BMS, also known as Protection Circuit Modules (PCM), is primarily used for protecting small batteries. Its functions are relatively simple and mainly include:

-

Basic Protection: Providing basic protection functions against overcharging, over-discharging, short circuits, and overcurrent.

-

Application Scope: Usually used for small lithium batteries, such as those in mobile phones and cameras, suitable for 3.7V or 7.4V batteries.

The design of PCB BMS is relatively simple, suitable for basic protection needs of batteries.

Main Differences

-

Application Scenarios:

-

BMS systems are suitable for large battery packs, capable of handling complex monitoring and management tasks.

-

PCB BMS is suitable for small batteries, mainly providing basic protection functions

[1].

-

Functional Complexity:

-

BMS systems have various monitoring and protection functions, capable of data analysis and communication.

-

PCB BMS functions are more singular, primarily focused on basic battery protection.

-

Design and Cost:

-

BMS systems have more complex designs and relatively higher costs.

-

PCB BMS has a simple design and lower costs, making it suitable for mass production

[2][3].

Conclusion

In summary, there are significant differences between BMS systems and PCB BMS in terms of functionality, application scenarios, and design complexity. BMS systems are suitable for large battery packs requiring complex management and monitoring, while PCB BMS is more appropriate for basic protection needs of small batteries. Understanding these differences helps in making more suitable decisions when selecting battery management solutions.

Learn more:

-

-

Share:

Novaic Golf Car Battery Receives UL 2271 Certification